This is a love story

I had spent four years scouring auctions to create a commercial kitchen.

We bought a tired, 1920’s-ish double-fronted gift shop in Shepparton at a time, just five years ago, when nobody much wanted to head to the bush, with a plan to split it down the middle. The left would be a long, skinny office (a decision led by the head). To the right, and in the back annexe of the building, would be an affair of the heart – a gelataria, pizza shop and cider bar that would fulfil my passion for all forms of hospitality, but most particularly for gelato.

The grease trap had to be craned in and dug into the hard Summer earth behind the shop. While we were there we plumbed in gas lines not just for the fryer, range and chargrill, but also for external heating for the garden out the back.

That was 2016.

Well before COVID-19 hit the hospitality sector, a planning department crisis hit Shepparton. It took a further 3.5 years to get my project through the planning department, and my love affair almost foundered then and there.

There were silver linings though. I spent a couple of years accumulating more gas appliances, I missed the COVID lockdowns and I coordinated the renovation of a couple of other places, including a new modest home for my mother, where she insisted the gas heater and hot water system had to be ripped out.

Despite the issues of embedded energy in creating the devices, and my incredulity at the persistent request to get out of gas, Mums project made me suddenly question what I was doing in the café.

With plans through, and climate change headlines hitting a crescendo, I looked around for advice on how to create a cost effective electric kitchen that chefs would want to work in and all I found was posts for really expensive equipment from manufacturers and a couple of blog posts saying how chefs hated cooking on anything other than gas.

As we finally planned for the fitout, I decided that while dismaying a chef may be costly, I couldn’t in all conscience install a gas kitchen in my new store.

I took the plunge. I sold all the appliances I had accumulated on ebay – some at a loss – and planned out a new, electric-only kitchen and hot water service. I would get cooking speed and control through commercial induction cooktops, high powered baking through a pizza oven, commission an electric hot water system to replace the gas and buy green power to top up generation from the panels.

The decision was easy, but…

The switchboard had to be upgraded to cope with new power requirements. Then the Power company had to upgrade the lines from the street to provide for my increased electricity needs. $5,000 later, I had nothing but a few switches to show for my brainwave.

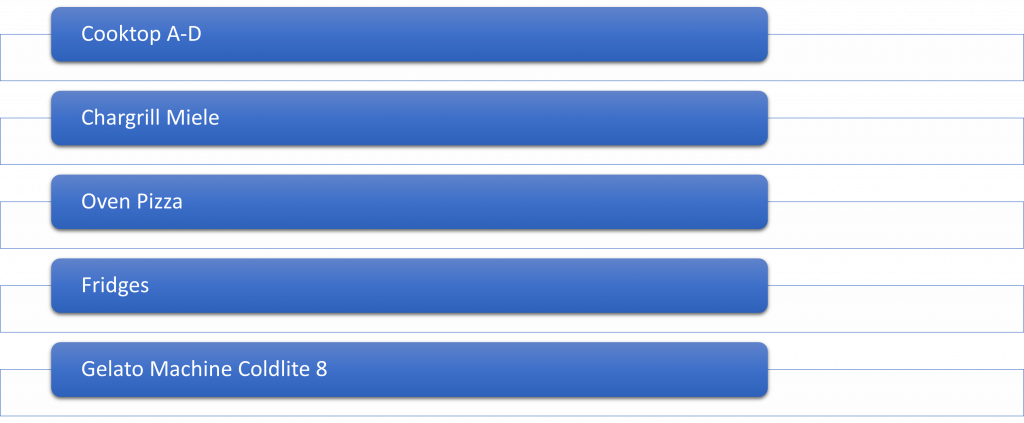

I found an electric chargrill, and imported it, then selected a range of wired in benchtop induction plates – chosen because they were middle of the road in price, and could be swapped over easily if I had chosen poorly, or one proved faulty. I figured it would be easier to change a wire than extract a failed device from a benchtop installation.

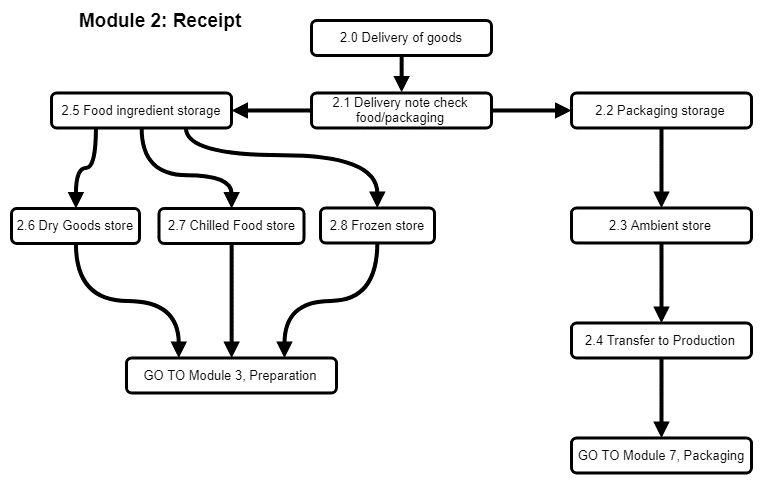

Kitchen workflow

Long time pizza eater, first time buyer.

I decided pizza sat well with gelato, and chose a double deck oven, thinking it would allow great productivity. I had never operated, let alone owned a pizza oven – except for a second hand gas one I bought on ebay earlier which took four men to lift into the shop and then turned out to be a complete dud.

I started off calculating how many pizzas I would ideally like to be able to make each hour in peak times and ended up choosing one which would take 8 pizza trays on each deck. Each pizza would take 5-7 minutes to cook ( a fact I am only working out now that I am trying out the oven) and so in a hypothetical ideal work a kitchen team could churn out more than 110 pizzas an hour, if everything lined up. In my cosy kitchen space, made smaller by my preference for gelato production, I would be lucky to prep, cook, cut and despatch half that number.

I had toyed with a wood-fired oven, but the complexity of fire setting and cooking, the potential carbon impact and the additional costs made me settle for a relatively inexpensive machine, which turned out to occupy more kitchen floor space than I had anticipated, but nonetheless has enabled us to turn out sets of really awesome pizza after just three experimental runs. High end ingredients and a commitment to local produce will eat into profit margins for pizza, but will set us apart from most other local competitors – so it appears that there is a strong opportunity for quality pizza output from opening.

Appliance selection

Sitting pretty, but ready to take a stand?

So far so good, but after all the electrical work, we were suddenly told that the 10kw of solar panels we had inherited on the shop roof had to go. Not only did the roof itself need to be replaced, but the single phase panels would not feed into the three phase system which gobbled up power for the pizza ovens, gelato machine and dishwasher – so we needed to upgrade the solar to a 3 phase system. Furthermore, the addition of rangehood vents and other rooftop items would restrict the amount of roof area that we could devote to solar panels. Suddenly, the climate responsible dream seemed a little further away. Costs were blowing out and the only good news financially was that as gas prices skyrocketed, we would no longer be affected.

But this project was about more than immediate returns – and I also believed that I might sell more from the gelateria if it was proudly carbon neutral. So we hauled down the old solar power system, and looked at fresh options.

NEXT: Solar, carbon-free gelato and the Big Electric Commercial Kitchen Fitout.